Never Conduct Your Safety Incident Investigation without This Timeless Roadmap

By : Admin -

Safety incident investigation provides a solid base for injury prevention efforts within any environmental, health, and safety (EHS) program.

It allows organizations to truly understand why and how undesirable events occur at their facilities. Thus, safety incident investigation supplies vital pieces of the puzzle when striving to prevent incidents from reoccurring.

For example, a tractor-trailer overturns at a site. The facility immediately institutes a lower speed limit on the property. However, this won’t necessarily prevent this incident from happening again. Why? The cause of the incident was a tire blowout, which caused the driver to lose control. Speed was not an issue.

Additionally, a systematic approach to investigative activities will lead to more accurate findings. When these types of assessments get conducted the same way each time, the possibility of overlooking or omitting facts or steps diminishes. The investigations produce robust findings, leading to better corrective and preventive measures.

Read on to uncover a safety incident investigation roadmap your operation can use to understand incidents better and choose practical actions to mitigate them.

Begin any safety incident investigation by selecting a team to conduct the investigative process.

All investigators should be well versed in the company’s procedure for investigating safety incidents.

Success starts with the procedure. An established, written process will serve the investigation team better than a “make it up as you go” approach. Assuming the organization has a standardized safety incident reporting procedure, an SOP for safety incident investigation serves as a logical next step.

The steps outlined in this post can serve as an initial outline if your site does not currently have a workplace incident investigation procedure. Additionally, the Occupational Safety and Health Administration’s Incident Investigation page provides great overview information and resources to help you get started.

Organizations should also standardize checklists, referenced sheets, or other templates to be used as part of the investigation process. Moreover, investigators should receive training as necessary to competently carry out the duties defined within the procedure.

An appointed lead investigator will have the responsibility of driving the investigation.

The team leader must have the authority to ensure the group adheres to standard practices. This individual will also be responsible for navigating scheduling, resource procurement, and status updates to leaders during the investigation.

The other investigators serve as collaborators who actively uncover facts, assess data, and determine causes and viable solutions. Therefore, these individuals are vital to completing the investigative objectives.

The size of a safety incident investigation team may vary with the investigation’s complexity. Less severe incidents will likely have smaller investigative crews. The group will often increase for larger, more complicated incidents.

Anyone participating in a safety incident investigation team needs to be free of bias.

Lead investigators should not be directly affected by the outcome of the investigation. Persons injured or involved in the incident should not serve on the investigative team in any capacity.

Direct supervisors of those injured or involved may bring valuable insight to the investigation group, but they are probably not the best choice to lead the effort. Remember, you want to avoid even the appearance of bias during the evaluation.

Base the rest of the team’s selection of the rest of the team on need, experience, and willingness to serve. The group should possess diversity to cultivate different perspectives. Furthermore, individuals outside the EHS function may also be necessary to meet investigative goals. For instance, if a piece of equipment failed as part of an incident, it makes perfect sense to include someone from maintenance on the team.

The investigation of safety incidents provides EHS engagement opportunities for workers. It gives chances for skill growth, discussion of safety issues, and participation in determining potential safeguards for the future. So, go ahead and ask for volunteers.

Image by Mediamodifier at unsplash.com.

Using the initial safety incident report as a guide, collect additional facts pertinent to the incident.

The investigation should start with facts immediately adjacent to the incident that may point to the event’s cause.

It would be prudent for investigators to take statements from involved persons, injured individuals, and any witnesses to the incident. Likewise, the team will want to procure necessary documentation like training records for the injured/involved party, maintenance records for any equipment associated with the event, and pictures or video, if available.

Other factual items essential to the safety incident investigation may include the supervisor’s statement, pre-operational inspection reports, daily examination records of the work area, and drug and alcohol test results for those connected to occurrence. After collecting the initial facts, the investigative team will want to review the data for omissions and clarity.

Additionally, the safety incident investigation will want to gather further information based on any questions or unclear pieces of evidence uncovered during the initial data collection.

The fact-finding process does not end after one review of the information. Questions are sure to arise from the data review. Investigators should work diligently to procure solid answers to those queries, meaning the team may need to obtain more data to support and explain the initial facts.

Information like manufacturers’ specifications, police reports (if any), equipment third-party certifications, or safety data sheets (SDS) could provide insight into the initial facts. Casting a wide net during the data collection process will provide a robust foundation to support the safety investigation’s findings.

Armed with the collected facts, map out a timeline of the incident.

The timeline should detail notable events immediately preceding, during, and after the incident.

Investigators need to clearly understand how happenings associated with the incident relate to each other to arrive at clear event causes. A visual representation of occurrences will help the team understand how things unfolded. This flow of events will simplify the discovery of the relationships within the incident’s events.

Focusing the investigation team on the most critical occurrences will help guide the effort toward a proper root cause determination later. For instance, the group may note that a vendor made a delivery at the front office right before an incident occurred. However, that event could be considered minor, especially if the vendor’s visit had no impact on worksite conditions.

Timeline creation can proceed in several ways. Tools like a Gantt chart or MS PowerPoint Basic Chevron Process SmartArt graphic can assist the group in streamlining the significant events associated with a safety incident. Likewise, a hand-drawn timeline can serve the same purpose. A plethora of timeline creation platforms also exist online. There’s even Office Timeline, an add-on for PowerPoint, to add you.

The timeline build is not the appropriate step for identifying causation in the safety incident investigation process.

While creating the timeline, investigators should work to discover correlations between the happenings associated with the incident. Is the timeline what the team would expect given the details gathered so far? Is the flow of events logical? Are there any events that seem out of sequence or foreign?

Remember, a connection between events does not always equal causation. Use the timeline creation as an opportunity to complete a secondary review of the facts. Don’t be afraid to ask more questions and collect more information if necessary. The end product should clearly and unbiasedly determine what, when, and where events occurred.

With the facts and timeline as support, the safety incident investigation team must ascertain and execute an appropriate root cause analysis (RCA) method.

Investigative teams should consider a variety of items when selecting an RCA methodology.

Investigators should weigh the risk associated with the incident before selecting a root cause determination approach. Some RCA methods possess a complexity that may be overly resource intensive for low-risk incidents. Alternatively, the team does want to choose a simplistic technique lacking the robustness to assess an incident with high risk.

A simple risk assessment can reveal where on the risk spectrum an incident lies. Start by assigning the incident a likelihood ranking of 1 to 5, where 1 is no or little likelihood of occurrence and 5 represents a substantial likelihood of the incident occurring frequently. Next, utilize the same ranking method to assign severity, with 1 meaning no injury, slight property damage and 5 equating to disabling injury or death. Now multiply your likelihood and severity rankings together to obtain a risk score. Your final risk scores will fall into the following categories:

- Low Risk: Incidents with risk scores of 1-8

- Medium Risk: Incidents with risk scores of 9-17

- High Risk: Incidents with risk scores of 18-25

Yet, the risk is not the only aspect for consideration when choosing an RCA method. Your organization may have already prescribed which approach(es) to use for determining the root causes of safety incidents. If the company has a defined process, investigators must follow it.

Also, the investigation team needs to look at the resources allocated for the investigative process. Some RCAs may require the purchase of software licenses and training. These activities may not be budgeted. So, considering more budget-friendly solutions that will still provide a robust evaluation may be warranted.

After RCA method selection, implement the RCA process to identify the safety incident’s primary cause(s).

The safety incident investigation’s next steps will be driven by the RCA methodology chosen. Brief overviews of three popular root cause determination approaches commonly utilized in safety incident investigations appear below:

- 5-Why

- One of the most straightforward analysis tools; provides a straight line to a single root cause.

- Best for lower-risk incidents.

- Uses deductive reasoning to arrive at the cause.

- Involves asking “why” at each stage of the analysis until the 5th cause (identified as the root cause) is reached.

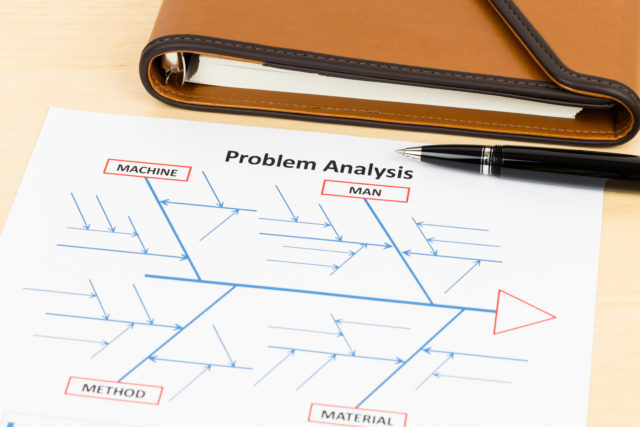

- Fishbone or Ishikawa Diagram

- Can generate multiple root causes for incidents.

- Best for low- and medium-risk incidents.

- Uses categories to map the effect (the incident) to potential causes (common classifications for safety investigations include people, processes, equipment, and environmental).

- Depicts a straight horizontal main line with category lines branching out like a fishbone would (hence the name).

- Involves brainstorming within the selected categories to identify all probable incident causes based on the facts collected.

Image by wirojsid at stock.adobe.com.

- Fault Tree Analysis (FTA)

- Only one undesired outcome (fault) evaluated at a time; can generate more than one root cause per fault.

- Best for medium- to high-risk incidents.

- Identifies root cause in a top-down approach using “logical gates” to depict associations between the levels of the tree.

- Involves finding all possible failures that contributed to the incident using brainstorming and data collected.

- Cross-functional team and additional training may be necessary to successfully this method.

- May want to use it in conjunction with a Pareto (80-20 rule) analysis to determine the causes contributing the most to the fault.

Many RCA tools exist and should be evaluated for fit within an organization’s safety incident investigation process.

Manual methods, i.e., trusty pen and paper, can help to build a solid RCA for the resource-strapped or technologically challenged. A 5-Why or Fishbone assessment can efficiently be completed by filling a template. Additionally, the team may opt to utilize brainstorm maps or sticky notes to help construct the cause determination.

Alternatively, open source software provides a good alternative for custom visualizations of 5-Whys, Fishbones, and FTAs. Google Drawings and Draw.io (now https://diagrams.net) cost nothing and are relatively user-friendly.

Businesses may also choose a paid RCA solution utilizing a software platform to organize and automate the process. Some of these choices have proprietary root case methodologies associated with them. Furthermore, the software may provide suggestions based on past data collected in the system. Additionally, these platforms may increase efficiency by pulling collected information from the database straight into the analysis.

Image by Shinpanu at stock.adobe.com.

In the next to last step of the safety incident investigation, rally the team to determine lessons learned and suggest corrective and preventive actions.

A safety incident investigation aims to determine root causes, facilitating hazard mitigation to avoid recurrence.

The lessons learned and corrective/preventive actions are where the investigation and injury prevention meet. So, don’t ever conclude an investigation without completing this step.

Lessons learned would constitute the list of informative tips that can be utilized in teachable moments for employees. These could be reminders of things they previously learned or new information uncovered during the safety investigation. Keep lessons learned brief (2-4 item bullet list) for easy incorporation into safety communications.

Teams should draw from personal and industry experience to devise valuable solutions to eliminate identified incident causes or lessen their risk.

The best way to mitigate an incident cause may not always be apparent. Investigators should be open to doing a little research to find possible corrective and preventive actions for undesirable safety outcomes. Case studies, trade associations, external subject-matter experts, and EHS professional groups may be able to provide information on potential solutions.

All the possible mitigation actions should be discussed within a cross-functional group as necessary and evaluated based on the Hierarchy of Controls and consider feasibility, cost, and timeliness to choose ones with the best fit for the organization. The group will want to look at all these aspects in relation to each other. For example, if effectiveness is vital, simply choosing the most effective option may not be best if the price tag may be too high or it may take too long to implement.

The corrective and preventive action selection process must be a collaborative effort. Remember, the team will be making the recommendations. So, all individuals should agree with the solutions presented.

Image by Manfred Steger at pixabay.com.

Round out the safety incident investigation with report creation and communication of findings.

The investigation report should provide an overall picture of what occurred, why it occurred, and suggestions to stop it from happening again.

A final report on investigative findings should provide the incident’s story from beginning to end. As such, investigative teams will want to include a few basic elements to ensure the report conveys the pertinent information. A standardized template can help to streamline the investigation report creation process and decrease the potential for data omissions.

Investigators should start by ensuring the report identifies the investigation team members and the dates the investigation took place. Depending on the length of the document, an executive summary may also be warranted. This recap should briefly outline the contents of the report.

Next, a narrative description of the undesired outcome should be composed. It may be helpful to chronicle the incident timeline created during the investigative review at this step. Additionally, the following section should detail the pertinent pieces of information collected during the fact-finding process. At this point, the report should note any evidence that did not make sense during the data review. Furthermore, identify any potential pertinent documents, images, videos, etc., that could not be obtained.

The RCA selection process and findings comprise the next significant section of the report. This part should detail the investigation’s approach, why that approach was chosen, how the RCA method was implemented, the root cause(s), and why the team feels those findings are valid. In short, the report needs to show readers the collective thinking of the investigative group in this portion of the document.

Last but not least, the report should end with an identification of lessons learned and suggested corrective/preventive actions. As with the RCA section above, some explanation of the safety investigation’s process to determine these items will bolster the rationale for the final recommendations.

The safety incident investigation cannot close without communicating the report contents to leaders for review, discussion, and action.

Safety investigation reports should be released to leaders initially for review and feedback. Managers and supervisors of the injured/involved party will want the opportunity to discuss the report findings before they are presented more broadly. Likewise, a manager/supervisor may wish to share the report’s conclusions with affected individuals before wider release, especially if disciplinary action is warranted.

The suggested actions in the report will also need to gain buy-in from leaders. Teams would not want to inform the workforce of a recommended corrective action that will receive a rejection from leadership. Moreover, managerial review and discussion allow those with authority to plan corrective or preventive action implementation.

Consequently, leaders will want to know what details will be communicated to others within the organization. They should be armed with all the information to field questions and provide workers with additional details as appropriate. An investigation closeout meeting with leaders and investigators may offer the perfect venue for efficiently conducting the leadership review and discussion.

After the leaders’ stamp of approval, the investigation results should be communicated to the workforce.

For employee communication, the investigation team should stick to the high-level information from the investigation report. A 2-page summary of the safety incident investigation should suffice. Be sure to omit any sensitive or personally identifiable information from these notifications to ensure privacy.

Sharing the safety incident investigation data with workers is primarily for educational purposes. So, the group should focus on the findings, the lessons learned, and the actions to be implemented to prevent a reoccurrence when crafting the communication piece. Turn to front-line managers and supervisors to disseminate the information during meetings, safety moments, and toolbox talks.

Safety personnel may even desire to incorporate specific incident investigation summaries into training sessions. Additionally, do not neglect bulletin boards, email, and intranet postings as part of the messaging strategy. Consequently, organizations will want to ensure the workforce stays apprised of the ongoing status of corrective and preventive measures through follow-up communications.

Other Posts Related to Safety Incident Investigation

EHS Management System Act Stage to Seal the Deal

Safety Incident Reporting for Those Who Don’t Fear Impressive Investigations

Risky Workplace Safety Compliance Mistakes to Recognize and Fix Before It’s Too Late

Concluding Remarks

Safety incident investigations only add value when appropriately conducted. A defined methodology for studying incidents aids in preventing future poor outcomes, boosts performance, and can positively impact culture. Using the roadmap outlined in the post will allow your operation to create an exemplary investigative process for its safety incidents.

Prorsa Consulting wants to hear your thoughts on this article. You can like, comment, and share if you find this information helpful. Also, feel free to leave your feedback on the Contact Us page.

Follow us on Twitter, LinkedIn, and Pinterest!

Helping companies enhance safety and environmental compliance is what Prorsa does. Ready to lower the risk non-compliant EHS can pose to your operations? A discovery call with us is an excellent place to begin. Get on our schedule today.

Would you like exclusive updates from us to help further support your EHS efforts? If so, subscribe to our free newsletter below. By doing so, you will also unlock our Free Resources page stocked with tools to assist you in creating a better EHS compliance program. Just fill out the form below to sign-up.